Able Designs and Construction Company (ADACC) and Dr. Ericsson Eguriase Otavboruo presents here a snippet of what was taught at the Project Development Institute (PRODA) in-house training on power inverter designed by Engr. Dr. Fabian C. Okonkwo to impart specific skills and practical knowledge to the staff of EPED.

A

power inverter is an electronic device that converts direct current (DC) from

battery or solar panel to alternating current (AC) which can power an electric

iron, air conditional, television, mobile

phone, computer and other domestic or industrial appliances. The generated AC power can carry these loads with the energy stored in the battery.

The inverter power is rated in VA or KVA.

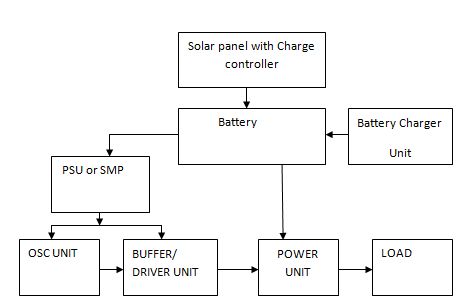

A simple power inverter consists of the units in the black box design shown below using top-down approach also known as step-wise design.

Power in VA = AC Voltage x AC Current in Amps

Power in KVA = AC Voltage x AC Current in Amps/1000

Power in Watts = AC Voltage x AC Current in Amps x PF

Where PF = power factor

Power in KW = AC Voltage x AC Current in Amps x PF/1000

Also Power in W = Power in VA x PF

Power in KW = Power in KVA x PFA simple power inverter consists of the units in the black box design shown below using top-down approach also known as step-wise design.

Block Diagram of a Power Inverter

A Simple Square wave Power Inverter Circuit

Protues Version of the Square wave Power Inverter Circuit

According to Pst. Engr. A. A Ndubuisi, one of the critical test for graduate engineers is in the application of technical knowledge in a way to solve engineering problems and to implement ideas in a cost effective and practical approach. The ability to take a thought or idea and translate it into a physical and workable product is what separates an engineer from other fields of science and mathematics.

EPED staff are trained by ADACC to think innovatively in order to design and develop electronic products from the initial vague concept to commercial production. Through the in-house training/workshop on COMPUTER AIDED DESIGN, PRINTED CIRCUIT BOARD PRODUCTION AND PROCESSING, SOFTWARE DEVELOPMENT, CIRCUIT DESIGN, MATLAB WORKSPACE AND SIMULINK, etc a lot of improvement has been done in EPED.

Thanks to Engr. Onyebuwa Ugochukwu. E who contributed immensely in the PCB production and processing during the 10th to 14th June 2019 training .

Oscillator: The oscillator unit in the above design is where the power

conversion takes place.

An oscillator is simply an electronic circuit that produces a

periodic or alternating signal. In

the design, CD4047 is used to design the oscillator unit

with good frequency stability.

The CD4047 is a multivibrator chip with very low

power consumption designed by TEXAS INSTRUMENTS. It can operate as a monostable and

astable circuit. It is one of the tricks that can generate 50% duty cycle which creates the pulse applied in the above circuit.

Buffer: The primary purpose of the buffer circuit in the design is to boost the current from the

oscillator unit.

A buffer

circuit is mainly used where a signal has a very low current which

needs to be increased. It can also maintain the same voltage level. The buffer circuit draws current from the power supply unit and adds it to the signal.

Power

Unit: The power unit

consists of a step up transformer and power transistors mostly MOSFET mounted on a heat sink.

This unit can use H-Bridge topology. It determines

the output power rating of the inverter. The battery supply is

given to the MOSFET to deliver the resulting AC signal to the step up

transformer in order to produce 220v AC at 50 Hz. The MOSFET can be IRF540 which is

a N-channel enhanced mode silicon gate field effect transistor.

Power

Inverter system plays a prominent role in ensuring uninterruptible power to

sensitive loads in PRODA. The waveform below is the simulated result of the square wave inverter.

The power inverter system also has a battery charging unit that charges the battery during

utility power. During utility power, the battery of the inverter is charged and

at the same time power is supplied to the loads. When utility power fails, the

battery system begins to supply power via the inverter to the loads.

The backup time depends on the number of batteries as well as the capacity of the batteries in Amp-hours.

The backup time depends on the number of batteries as well as the capacity of the batteries in Amp-hours.

To calculate the inverter battery backup time

It is calculated as:

It is calculated as:

Back up time = Battery Power in Watt hour

(Wh)/Connected Load in Watts (W)

Battery Power in Wh = Battery Capacity in AH x Battery

Voltage (V) x Number of Batteries.

Let

us shorten the formula by using the following Symbols:

Let ABLE = battery backup time in hours

C = battery capacity in AH

V = battery voltage in volts

N = Number of batteries in

series or parallel as the case may be.

PL = connected load in

watts (W)

Now

ABLE = C∗V∗NPL

Suppose we will selected a 24V, 1.5KVA inverter system that

is to use two 12V batteries in series connection and suppose the

capacity of our batteries are 200AH each,

then :

C

= 200AH

V

= 12V

N

= 2

PL = 1,060W

ABLE = 200 ∗ 12 ∗ 21060 = 4.53hrs

ABLE = 200 ∗ 12 ∗ 21060 = 4.53hrs

DR. ERICSSON EGURIASE OTAVBORUO can be contacted for MATLAB designs through the Director of EPED in PRODA. We shared IET journals and

electronic magazines to all the participants and IT students in EPED because we discovered that some design secrets and ideas are hidden in application notes, engineering journals and hard to get data books. Therefore, the vital information including job

opportunities and advert for professional development courses can be found there. To get more

journals and magazines visit: www.theiet.org/magazine.

These magazines should be considered required reading to keep up with

the latest electronic products and circuit ideas. The advertisements are as

important as the articles

...................................................................................................................................................................

THE

IN-HOUSE TRAINING AND WORKSHOP TEST ON CAD AND ELECTRONIC DESIGN

Conducted

by Able Designs (A member of Schoolnet and

business partner of IET, U.K).

Instructions:

Answer

all questions in part one.

Part

One: Questions

and Answers. Time:

30 minutes

1. What

is CAD?

2. Describe

the features in Proteus 8 as CAD software?

3. What is the

correct and full meaning of the following acronym in Protues 8 CAD suite?

A.

ISIS

B.

ARES

4. Use the CD4047

oscillator formula given during the training programme to get a 50 Hz frequency

output for the inverter?

NOTE: Kindly

show all the mathematical steps used to achieve the answer.

5. Design and draw

a complete schematic circuit diagram of the CD4047 power inverter and determine

its component values for 1 KVA, 220v AC, 50 Hz and 24v DC Design specification.

6. Name

the three main type of

PCB?

7. What is the four parts of PCB?

8. What are the basic steps to develop a product idea?

9. Explain

the following in Protues 8 and their uses

a.

Board Edge

b.

Selection Mode

c.

Component Mode

d.

Package Mode

e.

Track Mode

f.

Via Mode

g.

2D graphics box mode

h.

2D graphics text mode

i.

Dimension Mode

Part

Two: Practical.

Time:

1 Hour only

Please do the hardware or software

implementation and present the work for confirmation.

1.

Identify all the physical components used in the

inverter design and use them to build a working prototype of the product on a

breadboard or veroboard?

2.

Design and simulate the prototype of the inverter design

in Protues 8 software without using any of the component values (except the IC)

used during the training. The design must be accurate and simulates with the

with the waveform showing on an oscilloscope?

For more information: Contact the Director, EPED Department PRODA, Enugu or ADACC on +2348037909203, abledesigns@yahoo.com

You can also join IEE which is now IET from